Jam and tomato sauce filling lineWidely used in tomato sauce, sweet sauce, peanut butter, sesame sauce, sand tea sauce, etc., it can be filled in various specifications of glass bottles, plastic bottles, tin cans, etc.

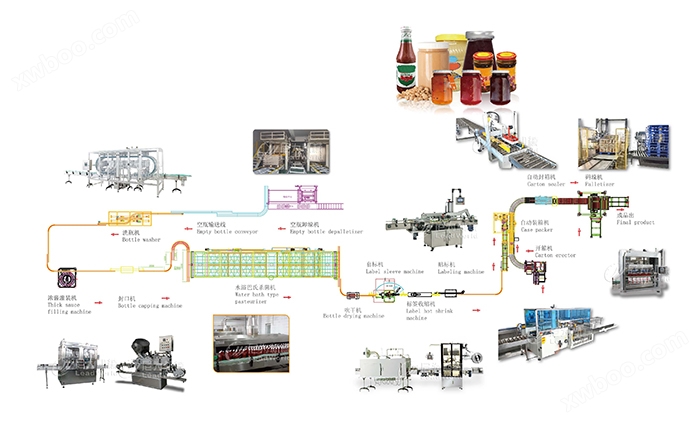

Jam and tomato sauce filling lineEquipment process

Empty bottle unloading - bottle washing - thick sauce filling machine - glass bottle sealing machine - sterilization machine - labeling machine - labeling machine - unboxing machine - boxing machine - sealing machine - palletizing machine

Jam and tomato sauce filling lineThe functional characteristics of

Empty bottle unloading

The unloading machine/unstacking machine is mainly suitable for automatic unloading and unstacking of various empty cans such as glass bottles that are stacked on the pallet. It lifts the empty cans stacked on the pallet layer by layer from bottom to top and pushes them layer by layer onto the conveyor, which can save a lot of manpower and improve production efficiency.

Bottle washing machine

The clamp type high-pressure bottle washing machine is mainly used for washing various glass bottles and iron cans, with automatic temperature control; This machine has achieved automatic bottle insertion and extraction, realizing the automation of the production line. The overall body is made of SUS304 stainless steel, which is beautiful and hygienic, with a visible hood, well manufactured, stable operation, and easy to use.

Strong sauce filling machine

Widely applicable to various industries such as food, beverage, seasoning, etc., it can be filled with different liquids and sauce products. Adopting Omron sensors, Siemens PLC, Weilun touch screen, and Schneider electrical components. Convenient adjustment, no bottle filling, accurate filling volume, and counting function.

Glass bottle sealing machine

This machine is a specialized equipment designed and manufactured for vacuum or non vacuum, spinning or sleeve sealing operations of screw mouth bottles (cans). It has the advantages of strong adaptability, high degree of automation, reliable sealing quality, convenient operation and maintenance, and beautiful and elegant appearance.

Sterilization machine

This machine is newly designed based on the absorption and digestion of foreign prototypes. It adopts a five stage process of circulating warm water preheating, circulating hot water sterilization, circulating hot water pre cooling, cooling water immersion cooling, and then cooling water spray cooling. It has the advantages of automatic sterilization temperature control and stepless adjustable sterilization time.

According to the different process requirements of heating, sterilization, insulation, and cooling for different products by users, different process designs can be carried out to meet the process requirements and configure corresponding high-precision automatic control systems. Compared to traditional water bath sterilization, the heat distribution is more uniform, permeable, and rapid, greatly improving production efficiency.

LABELLER

The automatic labeling machine is suitable for labeling the bottle body and mouth of round bottles, square bottles, conical round bottles, and curved bottles. Widely used in industries such as food, daily chemical, and pharmaceuticals.

labeller

Siemens PLC, touch screen, and servo motor are used as the main components to control the high-speed operation of the equipment.

The interface is friendly and easy to set up. The main functions include product counting, output setting, parameter memory, equipment status monitoring, automatic shutdown due to equipment failure, alarm prompt for fault location, and help function.

case erecting machine

The automatic unboxing machine adopts PLC+human-machine interface control, and the bottom folding does not stop. The bottom folding and sealing are completed during transportation; Simultaneously complete the entire process of suction box, molding, folding bottom, and sealing bottom; Easy to operate, simple to maintain, and stable in performance, it is an indispensable assembly line equipment for automated large-scale production.

case packer

The chain wheel packing machine has the characteristics of simple structure and easy maintenance. It uses Siemens PLC, Danfoss frequency converter, Schneider low-voltage electrical appliances and SEW motor, and the overall performance is stable and reliable.

Sealing machine

The sealing machine uses instant adhesive tape to seal the cardboard box, which is economical, fast, and easy to adjust. It can complete the upper and lower sealing actions in one go. The use of printing tape can also enhance the product image.

palletizer

Robot palletizer is a high-tech product of mechatronics integration. The fully automatic palletizing machine for medium and low positions can meet the production needs of medium and low output. We can stack various products such as material bags, rubber blocks, and boxes according to the required grouping method and layers. The precise design ensures a tight and neat stack shape.

Shanghai Niwei Machinery Technology Co., Ltd. is a company that integrates the development, research, production, manufacturing, marketing, and import of automated canned food production lines, filling production lines, and packaging systems. With its strong technical strength, market demand orientation, and product development as its responsibility, we can provide you with economical and reasonable solutions.